While Adam had the bed off his C-10 for chassis refinishing, he decided to overhaul his old brake lines. The original equipment brake lines were rusting from the inside and showing signs of fatigue from past work. The original flares were leaking as well, and the heads of the fittings […]

Tag: brakes

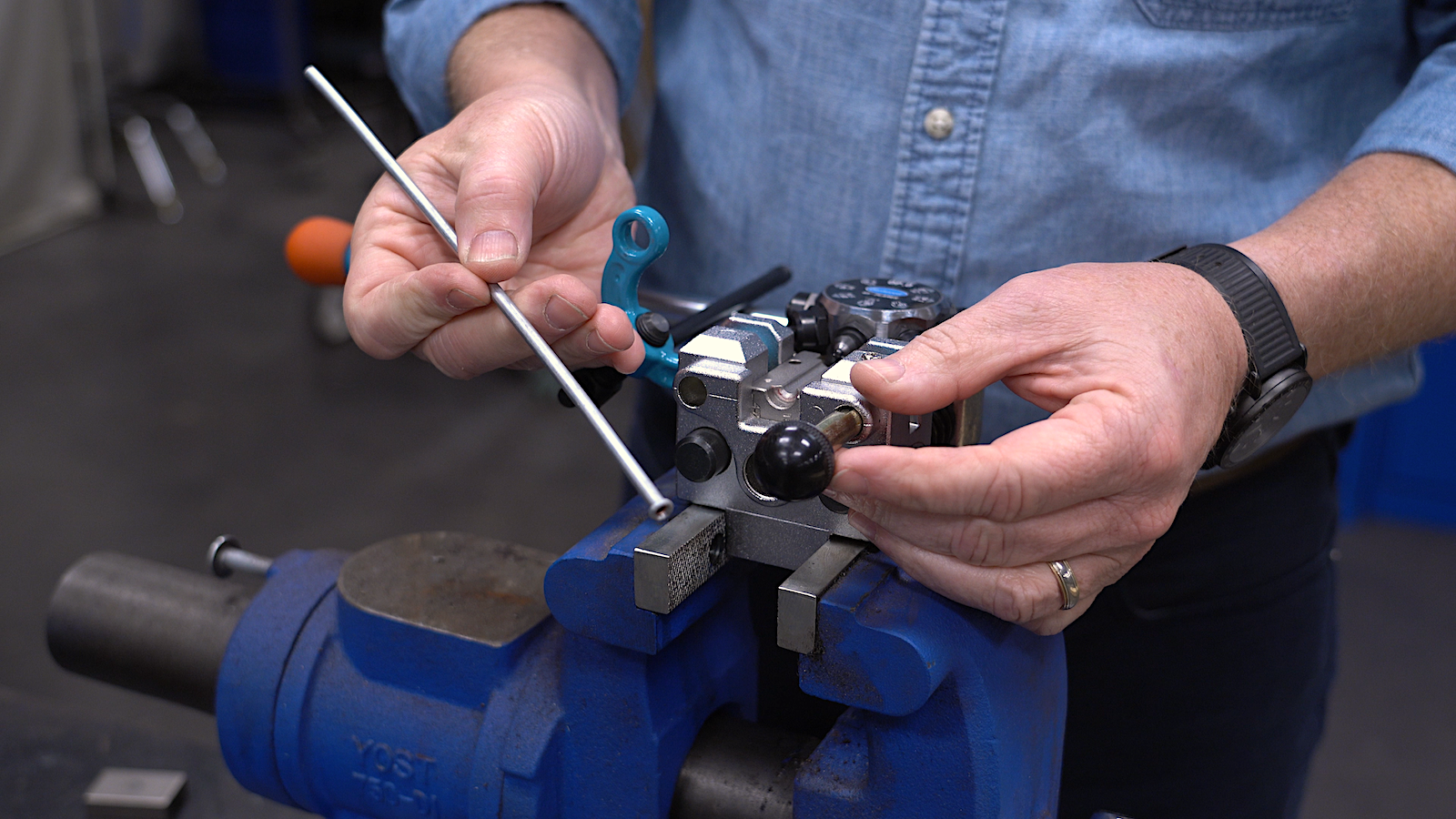

How To Form Perfect Brake Line Flares

Replacing brake lines or fuel lines is never fun. One of the most frustrating challenges of making new lines from scratch is getting a good flare on the end. And without a good flare, you’re practically asking for future leaks. There are all kinds of tools to make flares, but […]

How We Painted Brand New Brake Calipers Before Installing Them

It used to be that brake calipers were merely hidden mechanical equipment not worthy of special finishes beyond maybe a cadmium plating. That changed in 1993 when Porsche introduced larger brakes on its new 3.6-liter 911 Turbo. Finished in glossy red paint, these filled the space between the five-spoke wheels […]

What to Do when Brake Pedal Goes to The Floor

A Soft Brake Pedal Could Mean Brake Trouble We take for granted how important our brakes are on our car. We go VERY fast in modern cars and expect them to stop VERY quick. This means that you need to pay great attention to your brake pedal and brakes on […]

How to Flare Brake Lines (Live Stream Episode)

There are 3 basic types of flared ends you are likely to see on most cars: The single flare typically used on lower pressure fuel lines fittings, the double flare used on the high pressure brake lines of most vintage cars, and the bubble flare used on most modern and many older imported cars. In the picture the single flare is on the right, the double in the middle and the bubble on the left. With the proper Eastwood tools it is easy to make any of these flares.

Plumbing Custom Brake Lines on Project Pile House

First of all, if you’re rebuilding an old car, whether it’s a full blown 100 point restoration, or an out-of-this-world kustom, you shouldn’t forget about completely redoing the brakes on your ride. Brakes are one of the most overlooked part of a build that can save your car and your life. Project Pile House is a full blown custom with little to be left original on the truck. It sits on a first generation Chevy S10 chassis, so the brake components on each corner are easy to get replacements for, but that’s about where it stops being easy. I recently decided to plumb the brake system on Pile House, and show you what goes into a project like this.

How to Make your barn or garage find road-worthy- Part Three Restoring the Brake System

Once you have the vehicle running and moving under its own power you’ll surely want to drive it around your property to see what else it needs. The big thing that may kill the fun is the lack of brakes. In my particular case the front brakes were partially seized on and the brake pedal just went to the floor. I decided to completely disassemble the system and show how to go through the brakes on your classic car…..

Tips and Tricks to Flare Your Own Brake Lines

The brake system in a modern car is very complex, but when you break it all down they all work the same. The simplest description is that the brake pedal is depressed which compresses a piston in the master cylinder creating hydraulic pressure that sends fluid to each corner of the vehicle and activating the brakes. The system MUST be air tight and free of any contaminates or air bubbles. The sealed connection at each brake fitting is made by tightening a brake line and fitting into an opening that is shaped the opposite of the flare. Once tightened, an air and fluid tight connection is made.

We have a Brake Pedal and The Firewall Becomes Three Dimensional

In the last update I was working on cutting out metal to make the firewall and mocking up my new brake pedal setup from Speedway. Since then I’ve been pretty busy making something from nothing. I had to initially tackle how I was going to mount the brake booster and […]